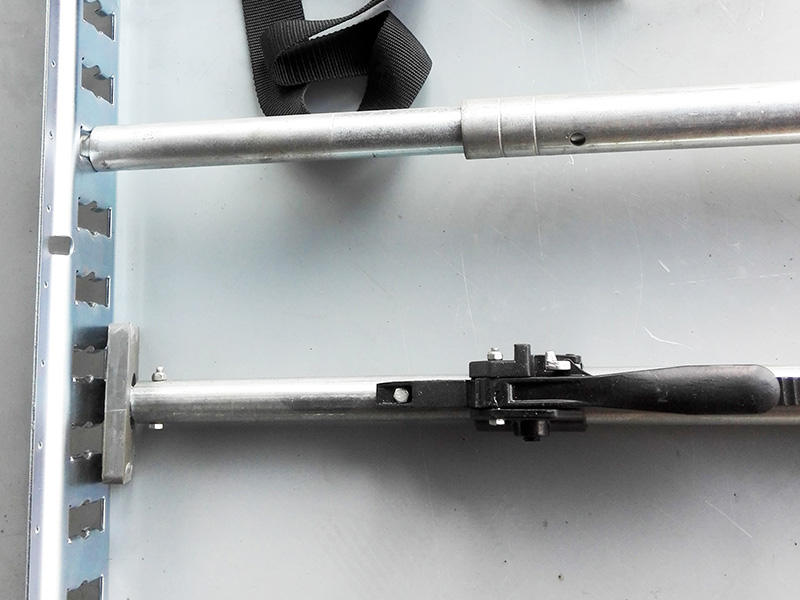

◆ Suitable for adjustment range: Any size.

◆ Suitable carriage temperature: Van body/refrigeration truck.

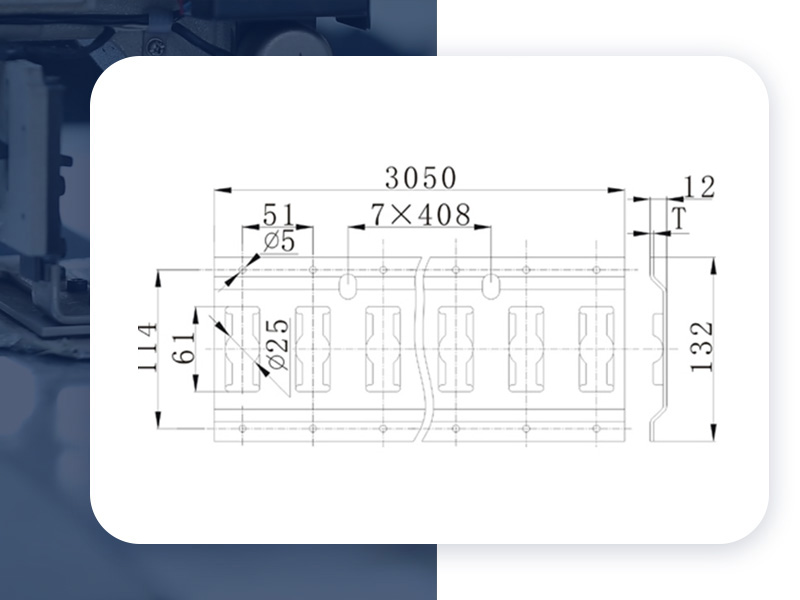

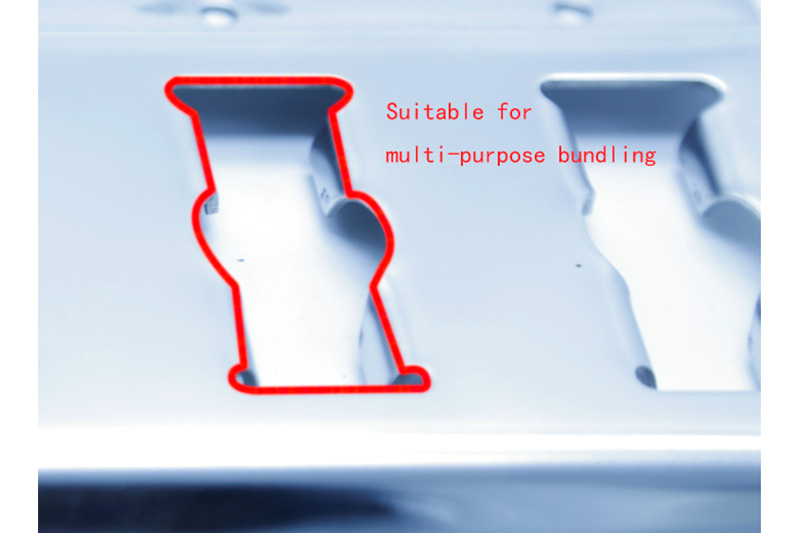

◆ Regulation type: "-" "E"type buckle & circular hole .

◆ Workmanship: Roll-in & punch.

◆ Design philosophy: Suitable for e-type buckle and round head pole matching use, and reserved drainage holes.

◆ The thickness of the type: 2.0MM or 2.5MM.

◆ Way to install: Bolt or rivet Unfold Install.

After installing the two ends of the support plate, it is better to match the corresponding end cover to prevent scraping!

Due to the different measurement methods, the measurement allows an error between 0.1mm and 1MM.

Due to the different colors displayed by different computers, the color of the actual product may be slightly different from the above image, affected by the physical object, thank you for your understanding.

Copyright © 2025 Truck Body Fittings Co., Ltd. | All Rights Reserved