Related Products

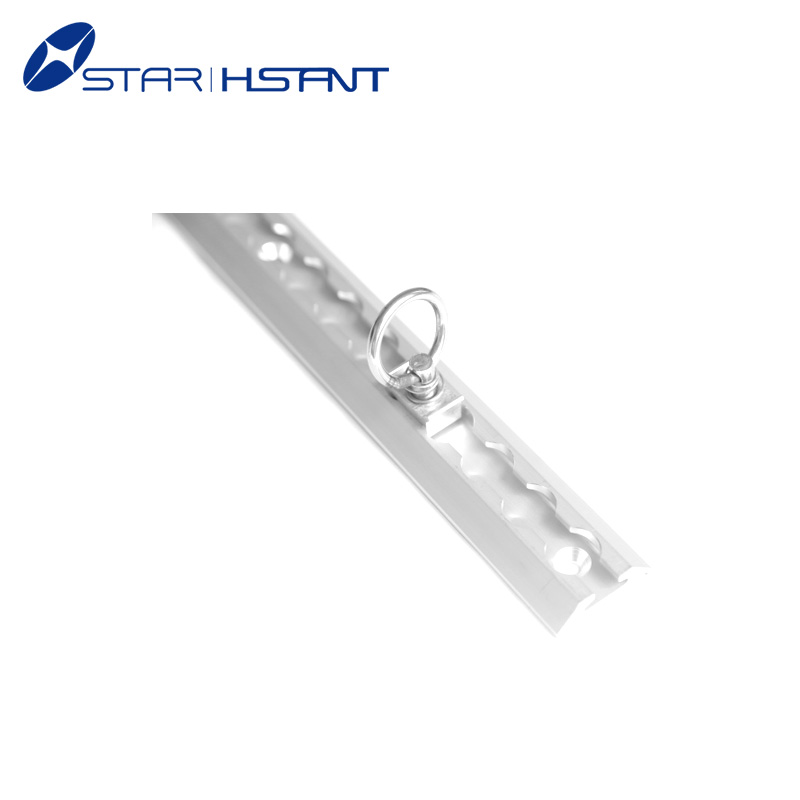

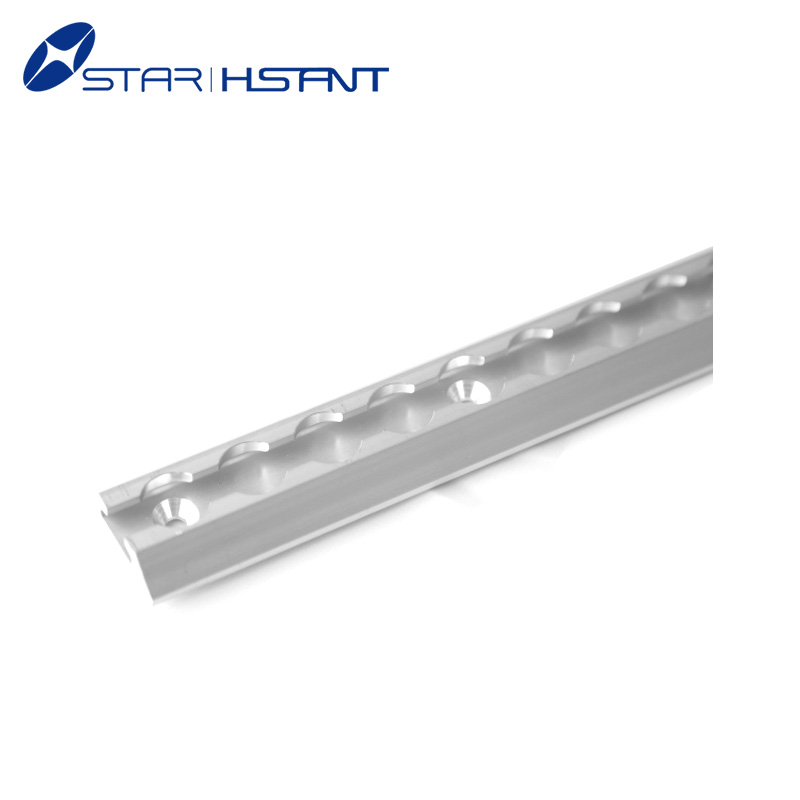

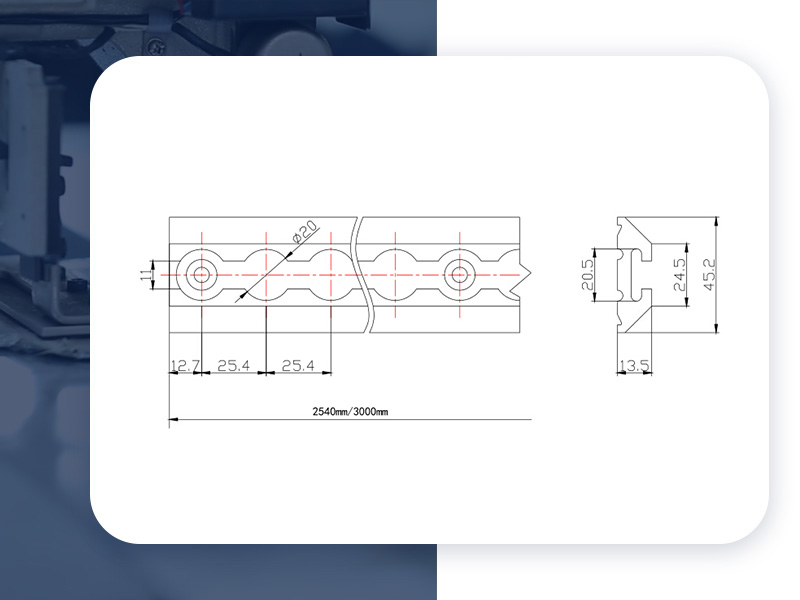

The maximum size of the product is within 3000MM, you can refer to this range to customize the size!

Due to different measurement methods, the error between 1MM and 5MM is allowed.

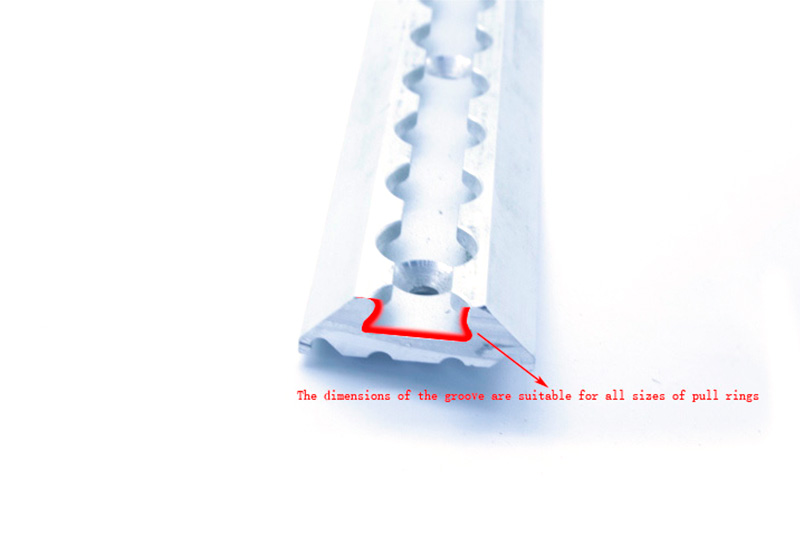

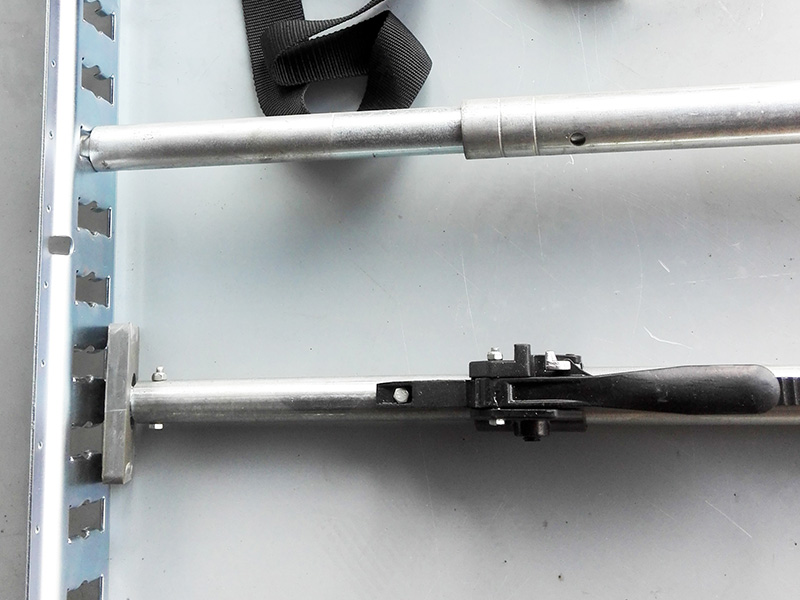

The image is slightly different, affected by the physical object, thank you for your understanding.

Copyright © 2025 Truck Body Fittings Co., Ltd. | All Rights Reserved