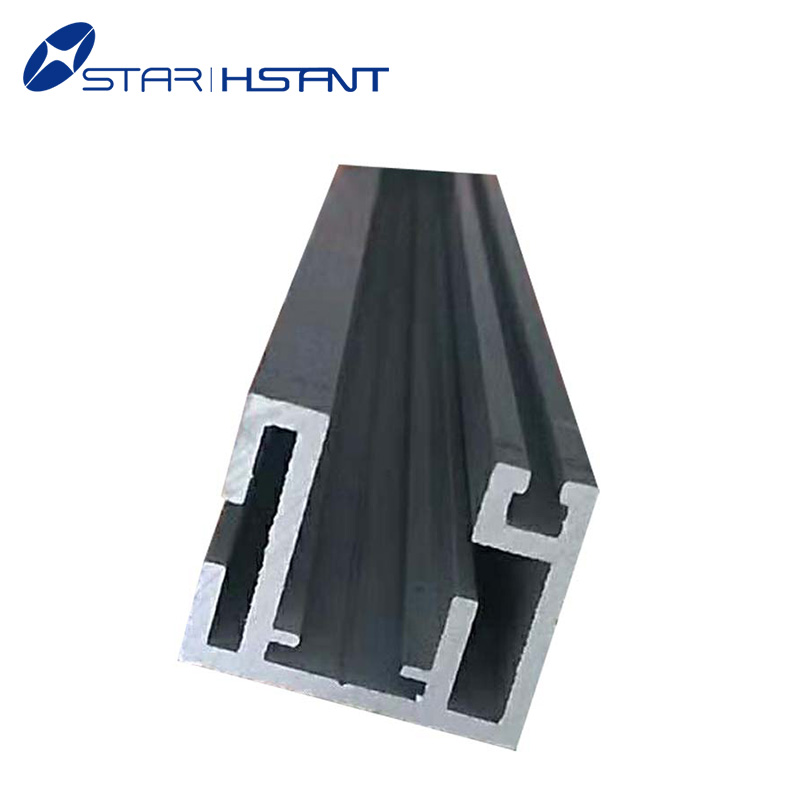

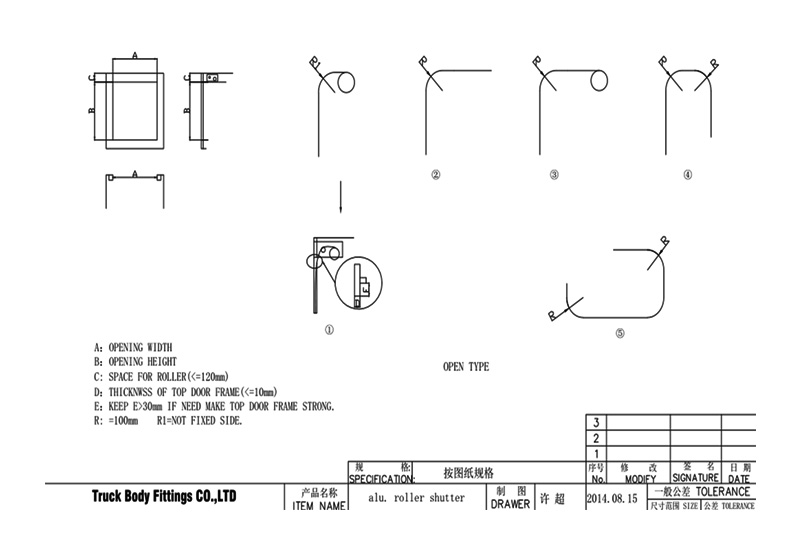

The thickness of the door frame on the upper end of the hole height should not be greater than 10MM!

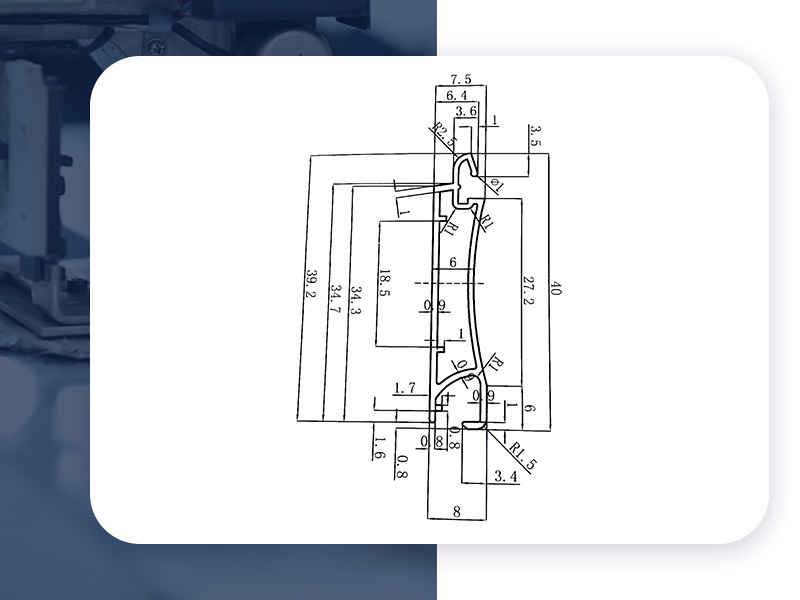

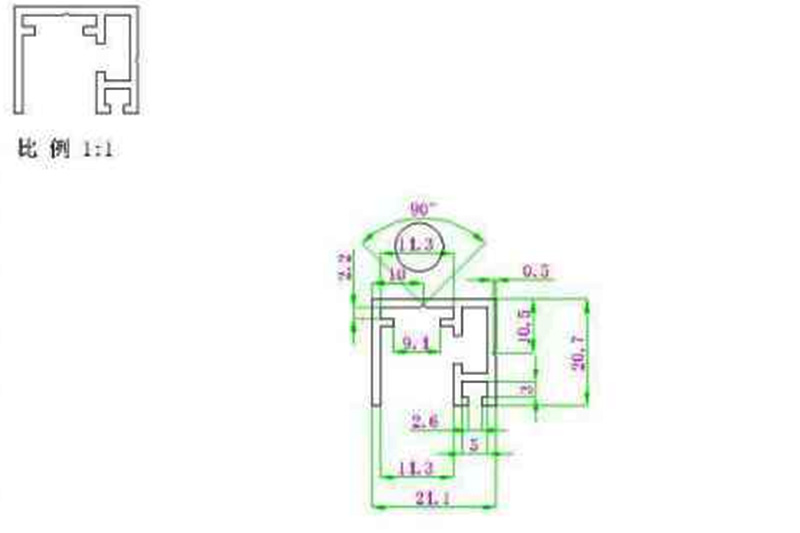

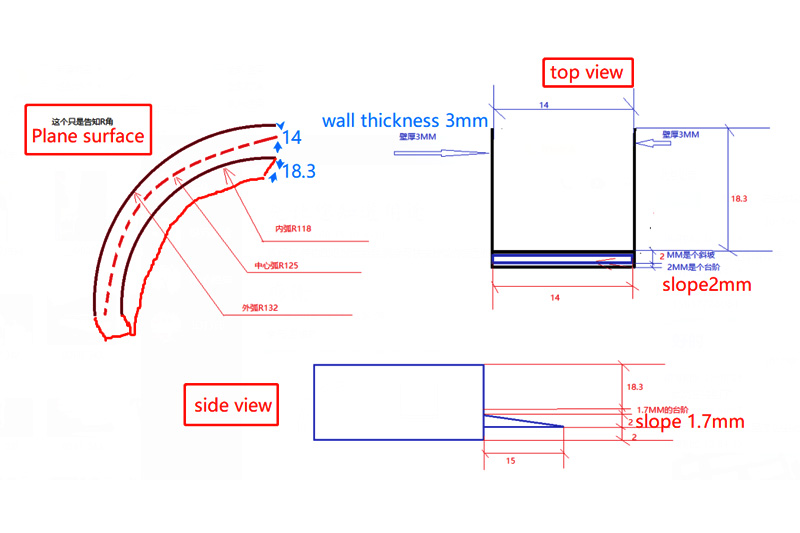

Due to different measurement methods, the measurement is allowed to be within 1mm-3mm error.

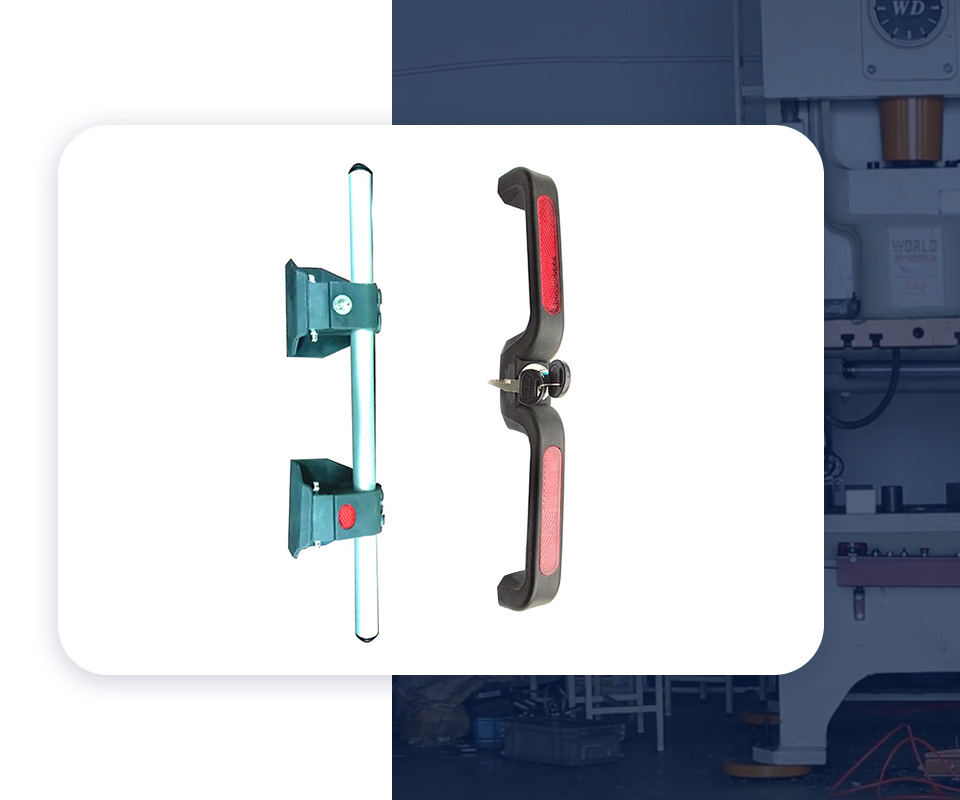

Due to the different colors displayed by different computers, the color of the actual product may be slightly different from the above image, affected by the physical object, thank you for your understanding.

Copyright © 2025 Truck Body Fittings Co., Ltd. | All Rights Reserved